3D Barndominium Design — Custom Blueprints, Realistic Visualization, and Build-Ready Planning

Big barndominium ideas deserve plans builders can use. 3D design bridges the gap between a concept you love and construction-ready documents. This guide explains how 3D barndominium plans, photoreal renderings, and virtual walkthroughs reduce surprises, keep you and your builder aligned, and speed permitting and material decisions for metal-home projects. You’ll get a clear look at what a 3D barndo design includes, how a builder-led workflow runs, which custom features are easiest to validate in 3D, and how visualization choices affect cost and construction in East Texas and Louisiana. We keep recommendations practical—integrated shops, open-concept living, and 2024 trends like sustainability and smart-home systems—so you can make confident decisions before breaking ground. Keywords we use here include 3D barndominium plans, barndo visualization, metal home 3d blueprints, and virtual barndominium tours to help with planning and discovery.

What Is 3D Barndominium Design and Why Is It Essential?

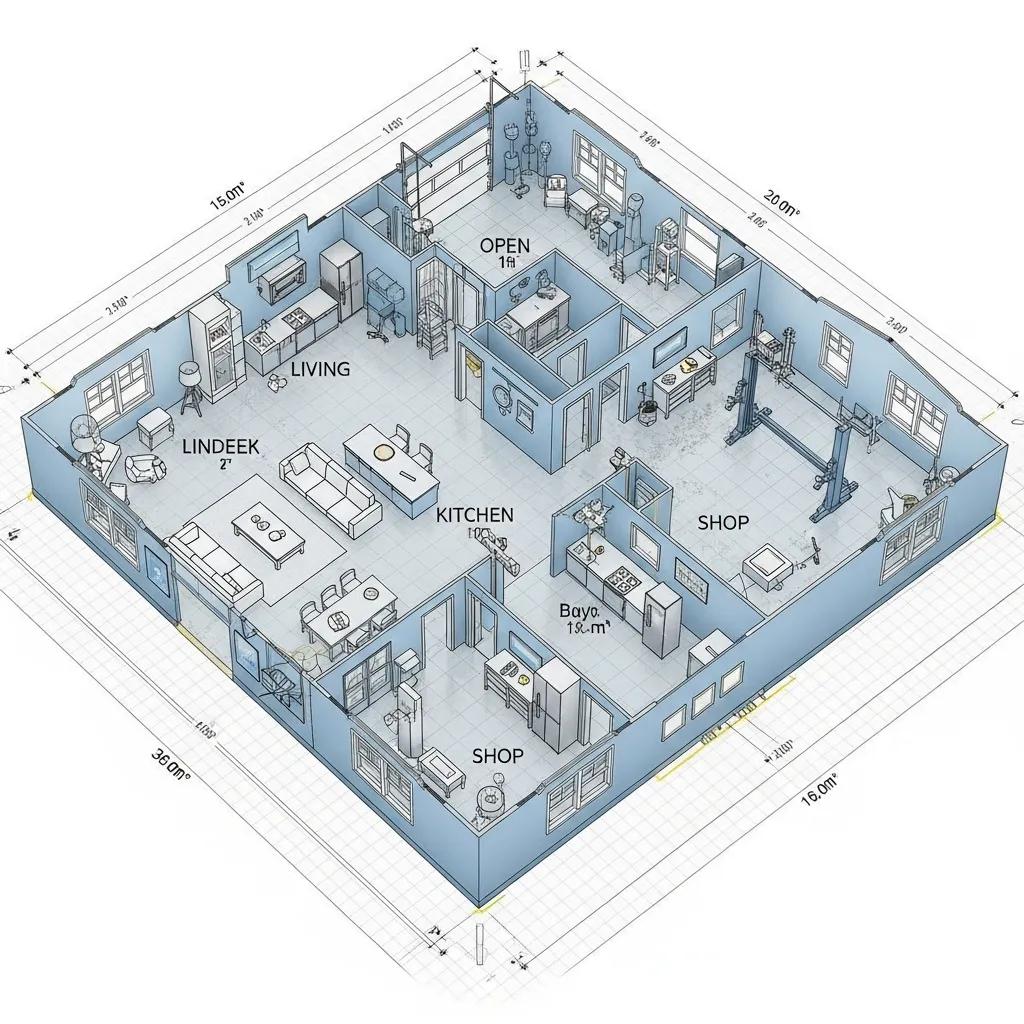

3D barndominium design creates a digital, three-dimensional model that pairs technical drafting with photoreal visuals and permit-ready blueprints so what you see is what you build. The model turns space, materials, and systems into measurable visuals that reveal conflicts early—things like roof intersections, mechanical chases, and shop clearances appear in the model long before framing starts. The payoff: fewer costly change orders and more accurate material orders because quantities and sight-lines are validated up front. For owners and builders, 3D work is both a communication tool and a quality check that aligns aesthetic choices with technical execution. From there, it’s easy to see how specific visualization deliverables—renderings and walkthroughs—improve decisions during design.

The clearest way to grasp this is to look at the core deliverables and the issues they uncover early in a project.

How Does 3D Design Improve Barndominium Visualization?

Exterior renderings, interior perspectives, and interactive virtual walkthroughs are the tools that let you judge scale, materials, and daylighting before a single board is cut. These visuals expose common layout problems—blocked sight-lines between living spaces and the shop, shallow porch overhangs, or tight clearances at garage doors—so the team can resolve them inside the model. A rendered kitchen elevation or a walkthrough of the master suite helps lock finishes and appliance placement, which reduces surprises during framing and trim. For owners planning from a distance, virtual tours give everyone the same reference so contractor decisions stay aligned with owner intent.

Interactive 3D Architectural Visualization with VR and BIM

This study examines how game‑engine methods can enhance architectural visualization and interactivity. The authors outline a prototype that links Building Information Modeling (BIM) with Virtual Reality (VR) to enable immersive walkthroughs and configurable architectural spaces. Using WebVR and a real‑time engine, the system gives stakeholders a hands‑on way to navigate designs and improves how teams interact with 3D architectural models.

The clarity from visualization leads directly to measurable gains when those visuals inform custom 3D blueprints.

What Are the Key Benefits of Custom 3D Barndominium Blueprints?

Custom 3D blueprints deliver precise spatial documentation that improves contractor coordination, speeds permitting, and cuts field change orders by producing accurate material quantities. Homeowners gain confidence because the permit set is derived from a validated 3D model—elevations, sections, and structural details match the visuals. Better accuracy up front typically shortens build time by preventing late design changes and clarifying subcontractor scopes. The bottom line: fewer delays, tighter estimates, and a smoother path from permit application to finished build.

That naturally raises the question of how a builder-led 3D process actually runs—from first meeting to final plans.

How Does Ross Homes & Drafting’s 3D Barndominium Design Process Work?

Our 3D process turns your goals into clear, buildable documentation through staged, collaborative work that leans on real builder experience. We begin with a site and context review and a program conversation to capture priorities—large shop bay, porch depth, vaulted living area. From there we prepare schematic 2D plans and elevations for your feedback, then build a full 3D model with realistic finishes and virtual walkthroughs for iterative review. Final deliverables are construction-ready blueprints produced from the validated model so the design intent lines up with field execution.

Ross Homes & Drafting offers 3D Drafting and Custom Home Blueprints as a local, builder-led service that emphasizes customization and visualization. Led by Travis Ross, a third-generation framer, our approach is hands-on and geared to help clients move from idea to build. Requesting a consultation is the next step to align the 3D model with your site and project goals.

Below is a concise, step-by-step summary of typical milestones and client checkpoints in a construction-focused 3D workflow.

What Are the Steps from Initial Consultation to Final 3D Blueprints?

The workflow follows clear phases that balance speed with revision control while keeping construction readiness front and center.

- Initial consultation and site/context review to define program and constraints, often followed by a survey or site photos.

- Schematic 2D plans and elevation concepts produced for client feedback and initial sign-off within 1–3 weeks.

- Conversion of approved schematics into a 3D model with material palettes and exterior options, then photorealistic images.

- Virtual walkthrough sessions where clients review the model and request updates; 1–3 revision rounds are common.

- Production of final construction blueprints and permit-ready documents derived from the validated 3D model.

These phases ensure every decision ties back to constructible details and recorded client approvals; the walkthrough phase specifically settles finish and spatial choices.

How Do Virtual Walkthroughs and Revisions Enhance Your Design?

Virtual walkthroughs let owners and builders resolve spatial and finish questions by experiencing the model at human scale—clarifying circulation, sight-lines, and furniture fit. Feedback commonly targets ceiling height perception, transition widths, and porch roof coverage—things hard to gauge on 2D plans. Iterative revisions within the model reduce ambiguity and create a documented approval trail; each approved change becomes part of the blueprint baseline contractors use on site. For clients outside East Texas and Louisiana, virtual sessions keep projects moving without frequent on-site visits.

What Customization Options Are Available in 3D Barndominium Floor Plans?

3D planning supports a wide range of custom features—from integrated shops and lofts to vaulted ceilings and large porches—and it quantifies trade-offs so you can prioritize with confidence. In the model you can test furniture layouts in an open plan, confirm clearances for shop equipment, and check sight-lines between kitchen, living, and porch. Because each choice affects structure, mechanical routing, and cost, 3D models let you iterate quickly and compare options. The table below shows common customization elements with drafting complexity and typical time-to-draft to guide schematic decisions.

| Customization Element | Drafting Complexity | Typical Time-to-Draft |

|---|---|---|

| Shop/Garage Integration | High — needs structural and access coordination | 1–2 weeks |

| Open-Concept Living | Medium — circulation and sight-line testing | 3–7 days |

| Vaulted Ceilings/Lofts | Medium — ceiling framing and mechanical planning | 4–10 days |

| Wraparound Porch/Outdoor Living | Low–Medium — roof and foundation interfaces | 3–7 days |

This table shows how different features map to drafting effort and turnaround, helping you focus early conversations on the high-impact choices.

3D tools also make it simple to try feature combinations and immediately see how square footage or framing trade-offs affect the build scope—leading naturally into layout-specific strategies.

How Can You Design Open Concept and Multi-Use Spaces in 3D?

Open-concept and multi-use areas benefit from 3D validation because models show circulation paths, furniture relationships, and acoustic conditions at full scale. We place virtual furniture and appliances to confirm clearances and sight-lines, then adjust columns or beams to preserve openness while meeting structural requirements. Lighting simulations help size windows and skylights for balanced daylighting, which also affects HVAC sizing. Iterating these details in 3D ensures multi-use living areas flow into shops or workspaces without sacrificing function.

What Are Popular Barndominium Floor Plan Features in 3D Designs?

Owners often choose features that increase versatility and resale value, and 3D modeling makes it clear how each feature fits the overall plan. Common inclusions are large attached shops with dedicated access and ventilation, vaulted great rooms with specific roof framing, and roomy porches that add usable outdoor space. Modeling these features uncovers structural and mechanical intersections early so we can detail them cost-effectively and avoid late scope creep. Prioritizing features in the 3D phase helps balance amenities with budget and schedule.

How Can 3D Exterior and Interior Visualization Elevate Your Barndominium Design?

Exterior visualizations let you compare metal siding, mixed-material facades, and window layouts to choose curb appeal suited to East Texas and Louisiana climates, while interior renderings show how finishes come together in kitchens and master suites. Side-by-side material swaps reduce indecision and expose construction interfaces—flashing, trim, and transition details—that need to be spelled out in the blueprints. The table below compares common exterior finishes and their visual and maintenance implications to guide early decisions.

| Finish Option | Visual Impact | Maintenance Implication |

|---|---|---|

| Steel Siding | Clean, industrial appearance with strong durability | Low maintenance; periodic inspections recommended |

| Wood Accent/Trim | Warm, rustic contrast with textured depth | Moderate maintenance; periodic sealing or staining |

| Composite Panels | Modern, smooth finish with customizable colors | Low–medium maintenance; good weather resilience |

This comparison clarifies how exterior choices shape the model’s visual story and the technical details in construction documents.

Interior visualization complements those choices by ensuring finishes, lighting, and layouts work together in kitchens, living areas, and suites.

What Are the Latest Trends in Modern and Rustic Barndominium Exteriors?

In 2024 we’re seeing a blend of industrial steel panels and warm accents with larger windows to create a modern‑rustic look that suits rural East Texas and Louisiana. Vertical metal siding paired with wood or composite accents improves curb appeal while keeping exposed areas low maintenance. Designers also favor matte hardware and deeper overhangs to control solar gain—choices we represent in renderings during design review. These trends help guide finishes that are both current and regionally practical.

Those exterior concepts lead directly into how interior renderings finalize layout and finish decisions.

How Does 3D Interior Design Showcase Kitchens, Living Areas, and Master Suites?

Interior 3D models show cabinetry, countertop textures, layered lighting, and furniture placement so kitchens function well, living areas feel right, and master suites are properly proportioned. We simulate fixture layouts, verify appliance clearances, and preview finish contrasts in photoreal images to reduce indecision. Lighting studies reveal where artificial light supplements daylight, guiding electrical and fixture placement in the blueprint set. When interior choices are validated visually, construction documents better match homeowner expectations and reduce field changes.

What Are the Costs and Value of 3D Barndominium Design Services?

Cost depends on scope—square footage, number of revision rounds, and deliverables (renderings, walkthroughs, permit sets). Typical packages balance conceptual work with construction readiness. Investing in 3D design delivers measurable ROI by cutting change orders, improving material takeoffs, and speeding permitting through clearer documentation. The table below compares common package tiers so owners can pick the right starting point for their project.

| Package Tier | Deliverables | Revision Rounds | Ideal Use-Case |

|---|---|---|---|

| Basic Concept | 2D schematic and simple 3D massing images | 1 round | Early planning and budgeting |

| Standard 3D | Full 3D model, photoreal renderings, and walkthrough | 2 rounds | Design development and permit prep |

| Premium Build Set | 3D model plus permit-ready blueprints and specifications | 3 rounds+ | Construction-ready documentation |

This comparison helps you weigh upfront design investment against the downstream savings from fewer field changes and clearer subcontractor scopes.

Ross Homes & Drafting structures its 3D Drafting and Custom Home Blueprints offerings around similar tiers and workflows. Our aim is to show expertise and guide homeowners toward a consultation that matches package scope to project complexity and regional needs.

How Does 3D Design Save Money and Time During Construction?

Savings come from fewer change orders, more accurate material takeoffs, and smoother subcontractor coordination enabled by validated 3D plans—reducing schedule risk and contingency spending. For example, resolving a layout conflict in the model prevents framing rework on site, and locking finishes earlier lets you order long‑lead items sooner. Permitting often moves faster when authorities receive consistent, clear documentation derived from the 3D model. Those efficiencies create a smoother build and more predictable cash flow during construction.

What Pricing Packages Does Ross Homes & Drafting Offer for 3D Plans?

Our service descriptions emphasize customization and visualization with a focus on building-aligned plans for East Texas and Louisiana. The 3D Drafting and Custom Home Blueprints service converts approved designs into permit-ready documentation, and review sessions are led by experienced framing leadership. We recommend requesting a consultation so we can match package scope to your project’s complexity and regional considerations.

What Are the Latest 2024 Trends in 3D Barndominium Design?

2024 trends emphasize sustainability, smart-home systems, steel-frame durability, and expanded outdoor living—each easy to model and evaluate in 3D before committing to construction choices. Modeling solar arrays, energy systems, and device locations helps owners compare performance and layout trade-offs early. Steel and industrial looks remain popular for durability and low maintenance, while expanded outdoor living—porches, covered patios, and integrated shop transitions—adds usable square footage and lifestyle value. Modeling these elements early ensures plans reflect current preferences and regional needs.

The primary trends shaping barndominium design this year are:

- Sustainability: Modeling orientation, shading, and solar integration to improve energy performance.

- Smart Home Integration: Planning device locations and control hubs in the 3D model for seamless automation.

- Steel/Industrial Aesthetics: Using metal siding and exposed structural elements for durability and style.

- Expanded Outdoor Living: Designing covered porches and shop transitions that extend usable space.

These trends are as practical as they are aesthetic—modeling them early clarifies both appearance and cost impacts for the final build.

How Are Sustainability and Smart Home Technology Integrated in 3D Designs?

Sustainability features—solar panels, rainwater capture, and optimized window placement—can be modeled to analyze orientation, shading, and energy impacts, informing both form and systems. Smart-home planning in the model includes device locations, wiring routes, and equipment spaces so systems coordinate with structure and finishes. Simulating these systems lets owners and builders weigh lifecycle benefits against upfront costs and arrive at a balanced approach that supports long-term value and comfort.

Why Are Steel Frame and Industrial Styles Popular in Modern Barndominiums?

Steel framing offers durability, weather resistance, and design flexibility that supports large shop bays and long-span roofs common in barndominiums—making it a strong choice for rural builds in East Texas and Louisiana. The industrial look pairs naturally with metal siding and exposed structure, and 3D models show how those choices affect interior volume and exterior composition. Modeling steel details early helps coordinate connections, thermal breaks, and finishes so the visual intent matches buildable reality.

Frequently Asked Questions

What is the typical timeline for completing a 3D barndominium design project?

Timelines vary with project size and complexity. Expect initial consultations and schematic designs in 1–3 weeks. Building the 3D model and completing revision rounds commonly takes another 2–6 weeks. Final construction-ready blueprints follow client approvals. Client feedback and the number of revision rounds will influence the overall schedule.

How do 3D designs accommodate future expansions or modifications?

3D designs are flexible and make planning future expansions easier. By accounting for possible additions—extra rooms or a larger shop—during the initial design, we can size structural supports and route utilities to simplify future work. Discussing potential growth early helps avoid costly retrofits later.

Can 3D barndominium designs incorporate energy-efficient features?

Yes. 3D models can include solar panels, energy-efficient windows, upgraded insulation details, and other features to evaluate their effect on comfort and performance. Simulating these elements helps homeowners make informed choices that improve long-term efficiency and lower operating costs.

What role does client feedback play in the 3D design process?

Client feedback is central. We review schematics, 3D models, and virtual walkthroughs with you so changes happen early and cheaply. That iterative loop reduces costly surprises during construction and ensures the final plans reflect your priorities.

How do 3D designs help in visualizing interior spaces?

3D designs let you see furniture layouts, fixture placement, and finishes in context before construction begins. Photorealistic images and walkthroughs show spatial relationships, lighting, and material combinations so you can make decisions with confidence and avoid last-minute changes.

What are the advantages of using a builder-led 3D design service?

A builder-led service brings practical construction knowledge into the design process. Builders understand sequencing, material choices, and local codes, which helps create plans that are both attractive and buildable. That alignment reduces change orders, improves cost estimates, and results in a smoother construction process—keeping the project grounded in regional realities and contractor perspectives.

Ready to move forward? Request a consultation and we’ll match the right package to your site and goals.

**